Check out our New Website!

Powder Coating

Fast Facts About Powder Coating

Fast Facts About Powder Coating

Fast Facts About Powder Coating

- Advanced method of applying a decorative and protective finish to a wide range of materials and products.

- Finely ground particles of pigment and resin are electro-statically charged and sprayed onto, pre-washed and surface etched, objects to be coated.

- The object to be coated is electrically grounded so the charged powder paint particles adhere to it until melted and fused into a solid coating in a curing oven.

- Powder painting is: tough, attractive, durable, scratch-resistant, high quality appearance, colorful, versatile, and long lasting.

- The process is environmentally friendly and virtually pollution free. Unlike liquid paint, no solvents are used, so no amounts of VOCs are released into the air.

Fast Facts About Powder Painting

Fast Facts About Powder Coating

Fast Facts About Powder Coating

- Our focus is low volume painting on either large or small parts. We can powder paint objects that fit within a 8' x 8' x 30' space.

- Quick turnaround - facilitating lean manufacturing operations.

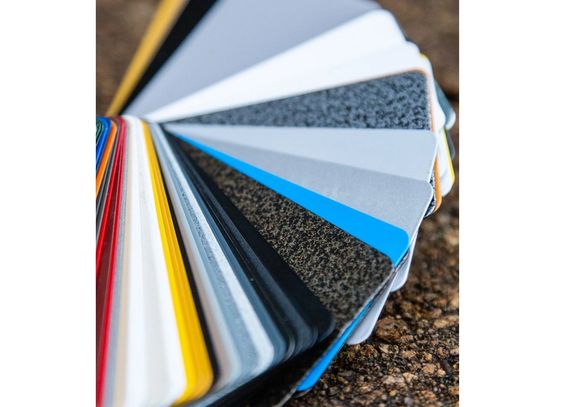

- Specializing in numerous colors and color changes.

- Customized projects with multiple colors and masking.

Call us to discuss your painting requirements

About Powder Painting

- Powder paint only comes in pre-made colors. They cannot be mixed. The most common paints are the polyesters which use the RAL color system (see below) but are available in some other stocked colors. Any special colors must be custom made which add cost and delivery time.

- Typically the powder paints come as high gloss. You can get some medium gloss and low gloss colors. There are additional ways to change the gloss for your application as well.

- There are various textured and metallic looking paints, all at higher costs.

- For the best durability and longest life in long term weathering or abusive service applications we recommend an epoxy primer undercoat with your color of choice for a polyester topcoat.

- We need to know about areas that need to be masked and plugged so they do not get painted.

- The most important thing to consider in your powder coating project is part preparation.

- Typical single coat wet paint thickness is less than 0.0005 inches. See chart below for typical single coat powder paint thicknesses.

Part Preparation

Customer Preparation

- Existing surface corrosion cannot be removed from incoming parts without some mechanical process like sandblasting, sanding, or wire brushing. This needs to be done by the customer. Corrosion will eat thru any coating, powder or other type. Unfortunately because of the various sizes we coat we do not do sandblasting.

- Please do not clean with any rust prohibitor or solvent as they can be very difficult to wash off.

- All greases, plastic parts, or any thing that cannot withstand 450 degree F must be removed as powder painting is heat dried and cured.

Our Preparation

All parts are cleaned and oven dried prior to be painted. We have a 3 to 6 step process for cleaning and use an iron phosphate pre-treatment for steel items. We use an etchant soap for aluminum or stainless steel items. Some folks will only sandblast parts prior to painting but powder painting experts believe cleaning with an etchant soap, like we use, is still necessary for long life.

Coating over coatings

- Powder coating is best utilized painted to bare metal but it can, just like other coating types, be applied over other coatings. The results will only be as good as the undercoat's adhesion.

- If the undercoats surface is very hard and/or smooth the paint will have difficulty adhering to the surface. We recommend mechanically roughing up the surface thru sanding or blasting.

- Also for better surface cosmetics we recommend taper sanding discrepancies in surface height on the existing surface, i.e. bare metal to old coating. A metal filler like JB Weld can be used to fill in major surface height changes.

Photo Gallery

Copyright © 2024 Quality Surface Processing - All Rights Reserved.

Powered by GoDaddy Website Builder